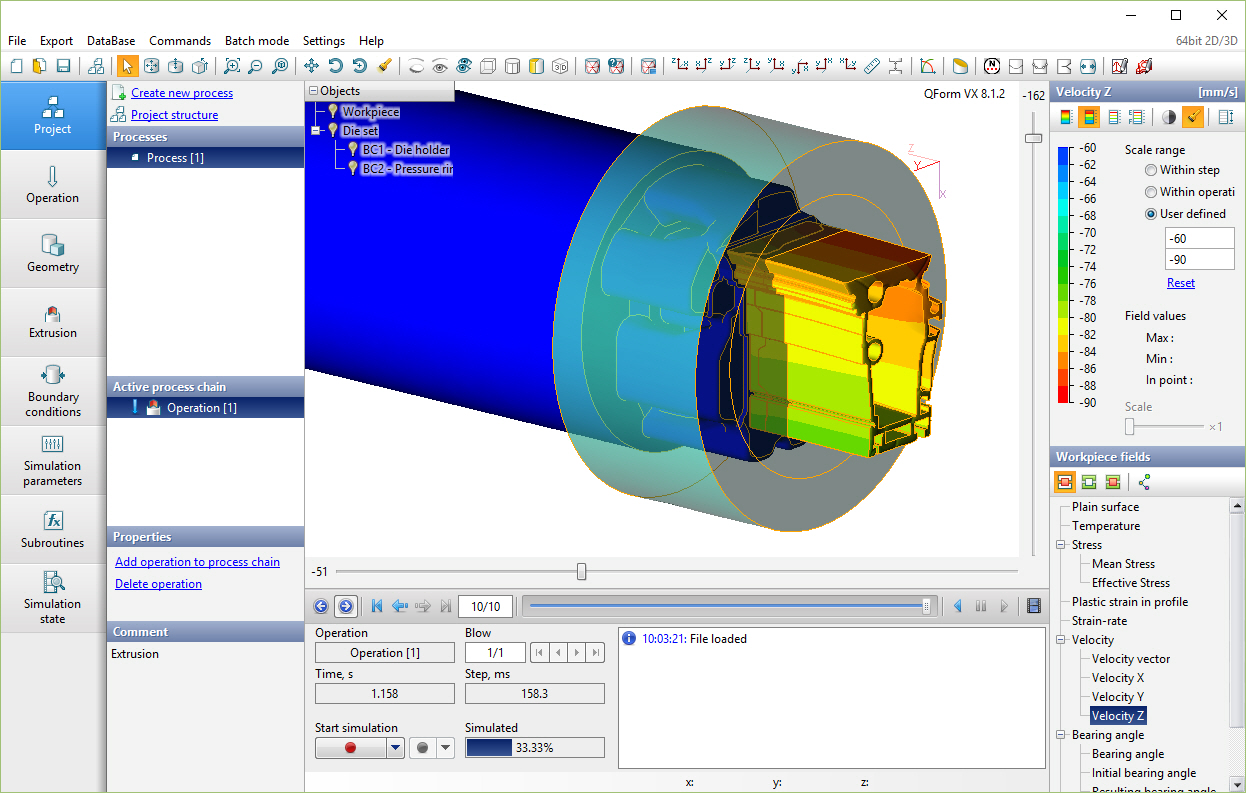

QForm VX is an engineering simulation and optimization software, developed by Quantorform Ltd. based in Russia and UK. The company is in business for more than 25 years and has clients in many industries inclusing Automobile, Aerospace, Defense, Energy, Education and Metal Forming. The software is being used for various Metal Forming processes including Forging, Rolling and Extrusion and can handle both 2D and 3D metal forming problems with ease. It has the most convenient user interface in the market which includes pre- and post-processor in one window.

QForm can simulate most metal forming process:

Why you need to use QForm VX software?

The software helps in the following areas:

- Reduce metal consumption by billet size optimization

- Increasing Tool life

- Reduce the time for developing and implementing of new technologies in production line

- Save time in designing and optimizing your tool & die design

- Predict hidden defects in finished products and improve the quality of your finished products

- Improve the communication within the company

Extrusion

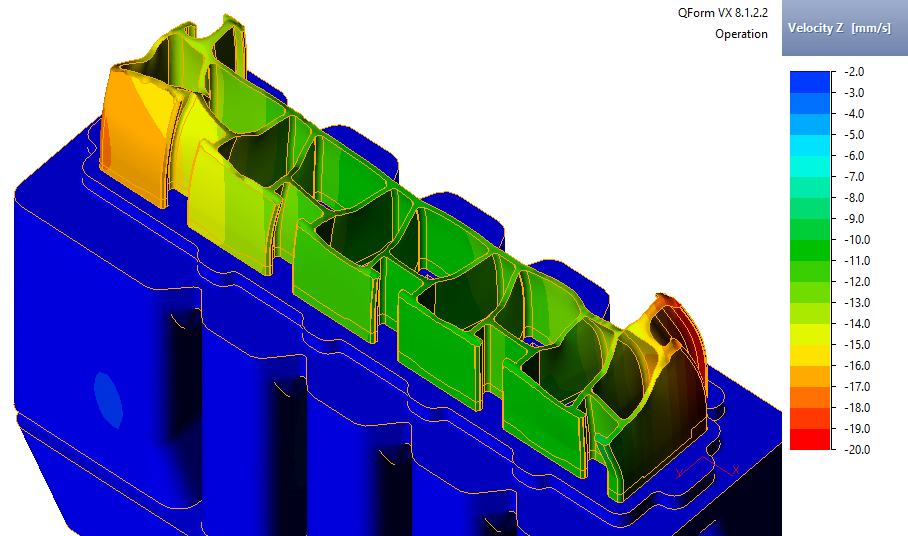

QForm Extrusion is the only extrusion simulation program that can calculate material flow fully coupled with temperature and deformation of the dies taking into considertation of the distortion of tool surface. QForm extrusion combined with QForm Extrusion die designer (QExDD) provides Die design integration seamlessly.

Features of QForm Extrusion:

- Simulates of any kind of profiles coupled with mechanical and thermal behaviour

- Fully automatic mesh generation and highly adaptive mesh in material flow domain and tool simulation domain

- Predicts of extrusion load, temperature, stress, strain, velocity distribution in any cross cut section

- Front end shape prediction

- Helps in optimizing Bearing height

- Longitudinal and transversal seams weld prediction, tracing of the points in the simulation

- Accurate calculation of entire billet heat gradient

- User defined subroutines calculation

- Report generation

Advantages of QForm Extrusion:

- Simulation of mechanically and thermally coupled problems of material flow and die deformation

- High simulation speed of the most complicated profiles thanks to a special Lagrange-Euler approach

- High adaptive tuning of the mesh helps very accurate results of the simulation

- An intuitive interface and easy input of initial data allow for a short learning curve

- Fully automated simulation process

- View and analysis of the results during simulation

For video demo on Extrusion simulation using QForm, please click here

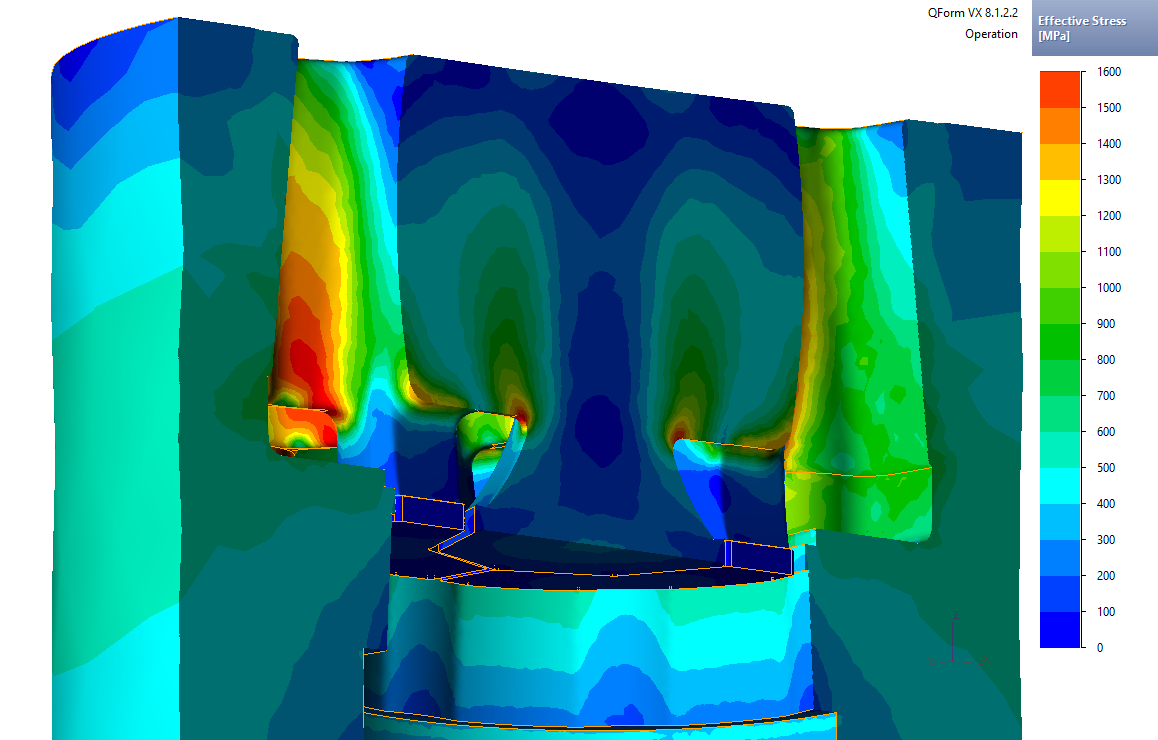

Forging

QForm can simulate any forging process, including hot, warm and cold forgings, open and closed die forging etc., very easily with any type of equipment. The software accurately predicts metal flow in different dies and possible defects including non-filling of a die impression, laps, flow through defects etc.

Features of QForm Forging:

- Can simulate the temperature, deformation and stress distribution in the workpiece and tool

- Simulate grain flow in the forging which contributes to quality of the product

- Predict accurate forging force and energy consumption analysis which makes it possible to select the suitable forming equipment

- Optimize the process to avoid defects

- Optimize the billet size and reduce the material consumption and enhance the productivity without costly trials

- Predict and improve the tool life i.e. increasing the durability of the tool/die

- Report generation

Advantages of QForm Forging:

- Short time to develop new tool

- Verification of the final shape of the forged part and quality of die filling

- Prediction of forged part properties

- Identification of forging defects such as laps, flow-through defects, underfilled areas and excess material ahead of time

- Prediction of tool life by tool stress analysis and identification of the zones that have the highest load and die wear

- Prediction of load and energy of deformation to verify the correct equipment choice

- The opportunity to see how the die cavity is filled to solve flow problems and find ways to improve the technology

- Solving problems related to production, for example checking the influence of the material quality or the quality of the surface of the machined product

For video demo on Forging simulation using QForm, please click here

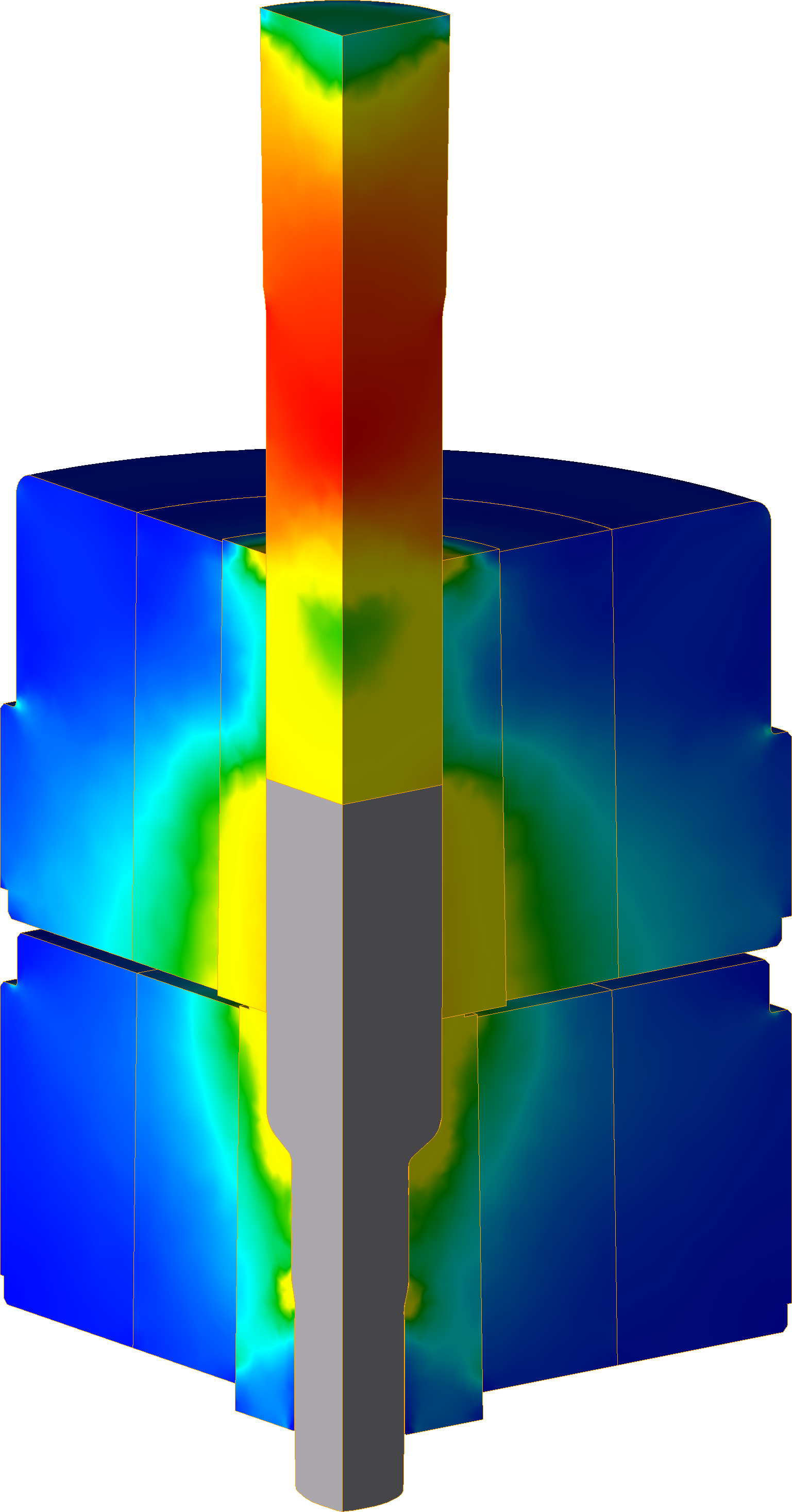

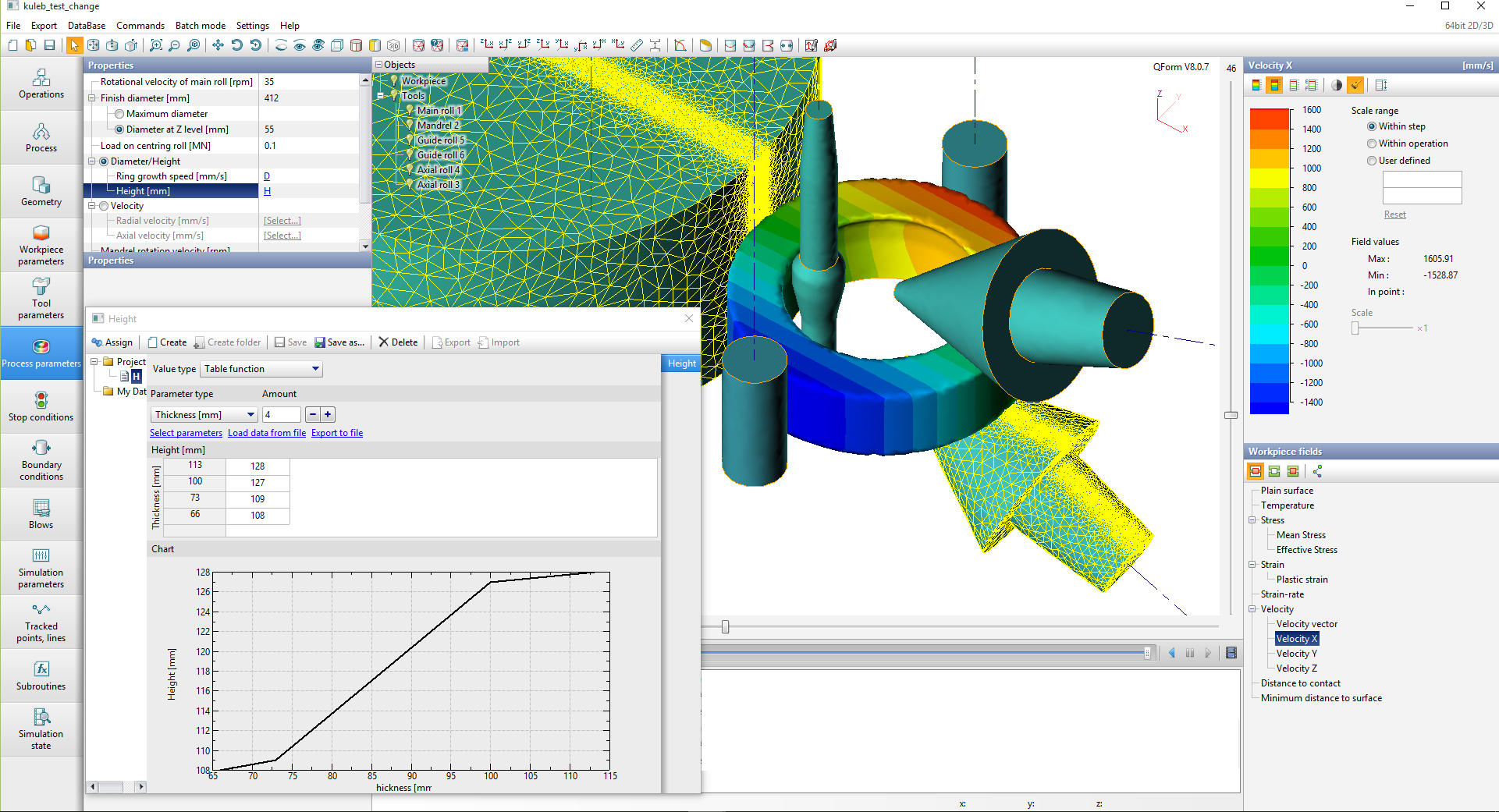

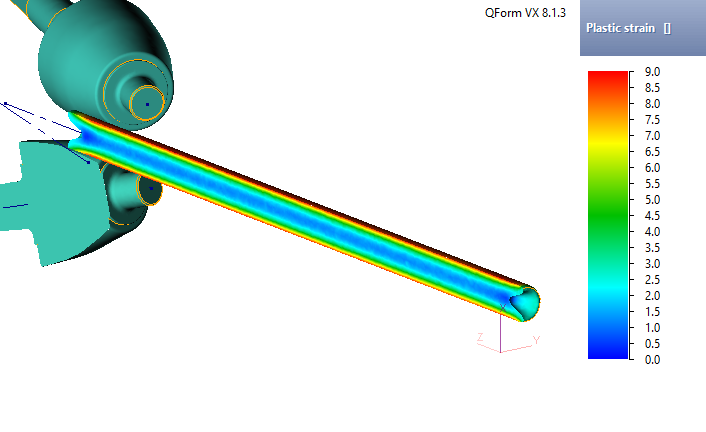

Rolling

As QForm is a multifaceted software, it can simulate even rolling processes including Ring Rolling, Reducer Rolling, Hot Flat Rolling and Cross wedge rolling etc.

Features that help simulate Rolling

- Special algorithms are applied to achieve high accuracy of formation prediction in processes where the workpiece is rotating during the process

- Automatic inheriting of rolling simulation results to subsequent forging operations

- Tracking user defined lines and points through the entire process for macrostructure prediction and for analysis of evolution of any field at specific points.

- Any point or line can be traced from the beginning of cross-wedge rolling operation to the end of the entire chain of all operations

- All chain of operations are simulated in one project file

Advantages

- Reduced technology development cost by testing on your computer without doing prototype or perform trials on a rolling machine

- Optimization of the entire forging technology chain including cross-wedge rolling process optimization by means of simulation in QForm

- Prediction of forged part properties after cross-wedge rolling operation, i.e. by analyzing temperature, effective strain field and macrostructure of forged part

- Determination of optimal workpiece shape

- Virtually designing the entire operation on your computer

- Using a virtual prototype for discussion with the customer offers a better understanding of the real process. Production staff can see inside the process that allows for better cooperation between engineers and technologists

For video on Rolling simulation using QForm, please click here

Training and Support

We are always ready to help you in case you experience technical problems with QForm to answer your question. QForm is a very user friendly software and it is very easy to learn. The help menu in the software is in-depth and it has examples with step by step guide.

To help you rapidly attain a higher proficiency we also offer a 2-day online training by an expert from Quantorform Ltd. If required, we can also visit your premise to offer you a custom training based on your needs and requirements.

For more information or to obtain a license, please contact us here.