Products

Our portfolio includes specialized Ansys solutions tailored to various structural engineering needs:

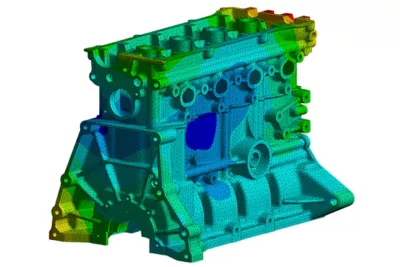

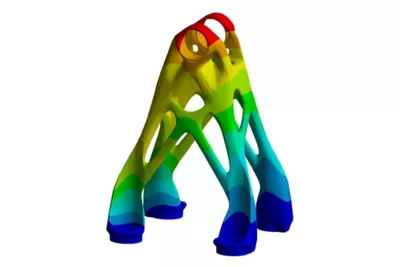

Ansys Mechanical

Address a wide range of structural analysis demands with a comprehensive finite element analysis (FEA) suite designed to deliver detailed insights into structural and coupled-field performance.

- User-Friendly, Versatile Solution

- Reliable and Robust Solver Architecture

- Fully Integrated, Adaptive Platform

Ansys LS-DYNA

Utilize a robust, explicit simulation platform seamlessly integrated with Ansys Mechanical. Its extensive capabilities and material libraries support large, scalable, and complex models.

- Handle Highly Nonlinear Simulations

- Model Severe Deformation Scenarios

- Resolve Multiphysics Challenges: ICFD, EM, CESE / Compressible CFD, and Reactive Flow

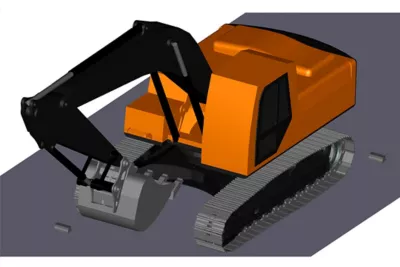

Ansys Motion

A multibody dynamic analysis tool for both rigid and flexible systems, enabling realistic assessment of physical phenomena through complete system modeling.

- Stable and Precise Solutions via Implicit Methods

- High-Speed, Accurate Single-Solver Analysis

- Exceptionally Fast Solver Technology

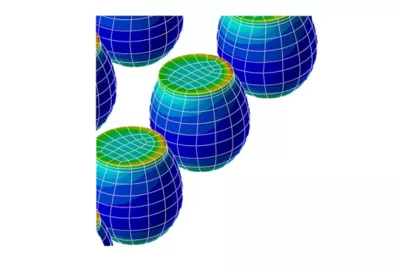

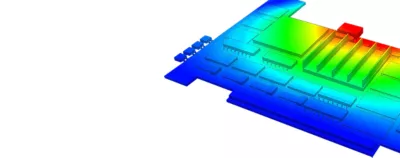

Ansys Additive

Deliver a scalable, all-in-one software suite that reduces risks in Additive Manufacturing (AM) while guaranteeing high-quality, certifiable outputs.

- Right First Time – Your Metal AM Components

- End-to-End Workflow: Build Prep, Simulation, Material Analysis, and More

- Standalone & Integrated Tools: Workbench, Discovery, and Granta Additive

Ansys Sherlock

Enable fast and precise reliability predictions for electronics across component, board, and system levels—starting at early design phases.

- Quickly Convert ECAD to FEA/CFD Models

- Transform Thermal-Mechanical Stress into Lifecycle Forecasts

- Flexible, Editable Embedded Component Libraries

Ansys Sounds

Blend multiphysics simulation with acoustic testing data to predict, refine, and improve product sound characteristics early in development.

- Comprehensive Acoustic and Noise Analysis

- Evaluate Sound Quality with Psychoacoustic Metrics

- Design Active Acoustics for EV and ICE Applications

- Audible CAE Simulation Output

- Jury-Based Sound Perception Assessment

- Immersive 3D Acoustic Simulation

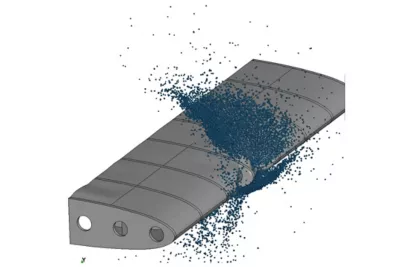

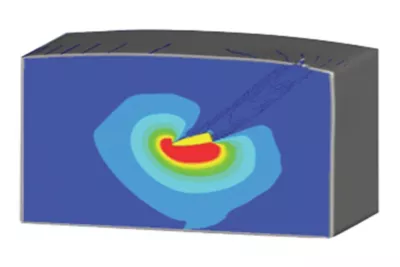

Ansys Autodyn

Model the material response to high-intensity, short-duration loading from impacts or explosive events.

- Powerful Simulation Capabilities Paired with Simplicity

- Multiple Solver Choices for Targeted Accuracy and Efficiency

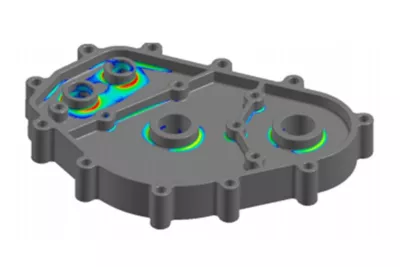

Ansys nCode DesignLife

Forecast product fatigue life by assessing stress, strain, and accumulated damage under cyclic loading, directly from FEA results.

- Seamlessly Embedded in Ansys Workbench

- Extensive Material Database for Quick Model Setup

- Early-Stage Optimization for Realistic Lifecycle Estimation

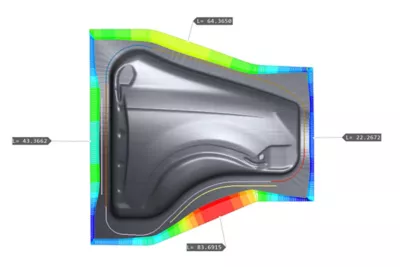

Ansys Forming

Simulate every stage of metal forming operations using a single, comprehensive workflow that ensures optimal processing speed.

• Intuitive, Streamlined User Interface

• Simulate Complex, Multistage Forming

• Design Driven by Process Insights

• Support for Multi-Lancing and Form Cutting

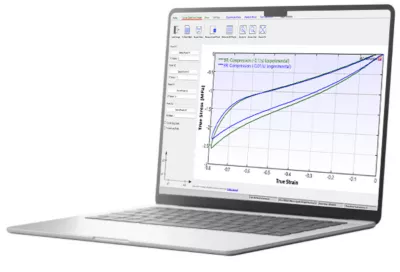

MCalibration

Tackle intricate material calibration with a feature-rich toolset that fine-tunes polymer property definitions for precise simulations.

- Detailed Calibration for Advanced Materials

- Highly Accurate Simulation Capabilities

- User-Friendly and Adaptable Interface

PolyUMod

Leverage advanced material modeling capabilities to improve simulation fidelity and predict material responses with confidence.

- Comprehensive Library of Material Models

- Support for Strain-Rate Sensitive Behavior

- Pre-Configured Material Datasets

- Wide Compatibility with FEA Platforms

Capabilities

Confidently navigate complex and diverse design environments with ease. A comprehensive suite of analytical tools empowers you to develop products that not only meet performance goals but also stand the test of time.

Get in touch with us

Collaborate with us to transform complex engineering challenges into smart, reliable solutions—driven by innovation, powered by expertise.

"*" indicates required fields